|

|

|

|

|

|

|

|

|

|

|

|

Last update :

14. 4. 2016 000 11:31

|

|

|

|

|

MOSAIC PANELS |

|

|

|

Mosaic panel advantages |

|

Demands on the big range of the controlling system emphasise the need for both good technical equipment and prompt decision-making by the operators. The latter plays the most important role in controlling difficult technological processes. They view most of the information on the monitors and on the controlling board. Displaying on the panel is very efficient ergonomically. It can give all information at once and at a determined location. Both kinds of displaying are very important in controlling systems. They don’t compete with each other, on the contrary they complete and they can substitute each other. APEL® produces and improves the construction of the board and provides guarantee to the people who work with it.

|

|

| View

|

|

|

|

| up |

|

| Mosaic panel description

|

|

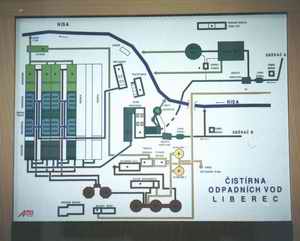

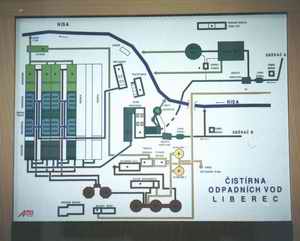

The modular system APEL® consists of the mechanical, electrical and software modules. We use it for Railway, Energy and Water Distribution controlling centres, but they are applicable with other technologies as well. The mosaic construction of front sides is suitable for a variety of schemes and for their easy adaptation to a system operation. The control is realised in accordance with the technology and thus technology potentials are utilised efficiently. Communicating devices are lighting diodes LED with guaranteed long service time and colour stability. The miniaturisation enables to design small panels and thus reduce space consumption.

|

| up |

|

|

Mechanical Contruction

|

|

The mechanical part consists of two basic components – a rack and a cover. Their shapes, connection and a 3-D arrangement are protected by an industrial patent. These components are made of high quality material – a well-constructed plastic. The plastic with antistatic ingredients is used in the rack because these ingredients guarantee equal (zero) potential on the entire surface, and dirt on the covers is reduced. The front side of the cover is 24 x 24 mm large and its surface is matt to prevent reflections. The colour of the cover is selected upon the recommendation of the Institute for Public Hygiene in Prague. The colour of the cover contrasts suitably with the LED colour and the displayed characters are easily readable. The cover dimensions are designed to enable incorporation of measuring, signalling or regulating devices by various producers, whose front sides are often in 24 mm multiples (for instance 48 × 96 mm). The technology is displayed by means of the colour stickers or silk-screen printing.

The rack with the covers is embedded inside the steel or aluminous construction. The wall construction enables to hang the mosaic on the wall. The switchboard construction is usually on a base support. The self-supporting mosaic panel and the base support are covered by metal doors at the back and usually by veneered boards at the front and on the sides. An architect recommends the shape and the design. The metallic parts are finished with powder colour. The mosaic panel is usually structured to structural modules, which can be arranged lineal or so that their ground plan is a broken line. A standard angle of 15° is used. The mosaic proportions are designed in accordance with the technology and requirements of a customer. The base support height is usually 810 mm, the cover and base support depth is 250 mm (without computers) or 650 mm (if it is necessary to install a computer – usually with an industrial design in 19´´case).

|

| Communication devices |

|

One- or more-coloured LED with different diameter display the technology conditions on the panel. In comparison with the bulbs used in older systems, LED has outstanding service time (over 200,000 hours), colour stability and low power input. It is possible to use not only red, green and yellow LED diodes but also blue and white at the present time. Red-green combination is used most frequently from among the two-coloured LED diodes. The LED diodes are placed in accordance with the design of the connector modules. It is possible to put LED diodes as single components or as compound components.

Besides LED diodes, seven-segment or 16-segment LED panel displays can be placed in the mosaic panels. These displays are 10 or 20 mm in height, green, red or yellow. It is possible to assemble a displaying board of any length.

The mosaic panel enables to include switches and controls, such as buttons, selectors or keys. The types with a 24 × 24 mm front side are used. Analogue or digital measuring devices and control devices in normalised casings in 24mm multiples, supplied by many producers in a large assortment, can also be incorporated in the mosaic panel.

|

|

| up |

|

| Control of the mosaic panel

|

Three basic types of a mosaic control are used in accordance with a range of a monitored technology:

the panel is controlled by a PC with a special card PT featuring the system image,

the panel is controlled by a serial module PSK,

the panel is connected directly to the technological processes by means of special electronic modules

|

| up |

|

| PC – Controlled mosaic panels |

|

The PC-controlled mosaic panel is determined for systems with many input signals from technology (e.g. regional energetic dispatching centres, high-capacity waterworks dispatching centres). There are usually concentrated data disposable and it is not necessary to transfer them to a parallel form. If you have to transfer them you need to supplement the operating system with many output modules. The price of this supplementation is proportional to a number of modules but also to a brand name of the supplier. It is necessary to keep it in mind during the estimation of the price of the mosaic panel and of all the costs of the dispatching centre.

The PC-controlled mosaic panel is determined for systems with many input signals (typically over 1000 signals).

The control computer is supplemented with one or more special memory cards (PT). These cards are put in free slots of the PCI data bus line. One PT card enables to control maximal 65 536 two-coloured LED diodes with a high comfort of a shine control. The shine may be modulated by 6 oscillators with a software-controlled frequency of the oscillation. The control of the shine intensity is software controlled, lossless in 14 levels.

The control computer may be placed up to 100 m far from the mosaic panel without any special modification. But it is most often placed right in a stand of the panel in a 19´´ case. The used computers are of technological construction and they are produced with high demands on reliability and mechanical resistance. Computer monitors are of industrial construction with a proper diagonal (19´´ to 21´´, or bigger).

The signals are conducted from the PT card to the mosaic panel, where the information is distributed to the display modules by means of modules MX. 8 MX modules can be connected to every PT card and 32 display modules can be connected to every MX module.

The JS module includes switching circuits that control the shine of LED diodes placed on the JK module.

The JK module includes 256 connectors and a two-coloured LED can be put in each of these connectors. This placement enables easy changes of the configuration of communication devices. They are only moved to another connector. The connector always has disposed the switching circuits on the JS module, relevant controllers on the MX module and a reserved memory space on the PT card. The new used position is built in the information system by means of a database modification.

All electronic section is projected to be elementary and reliable with the minimal take-off. The general supply is given by the own power consumption (c. 10 W), the power consumption of the LED diodes (40 mW at every shining microchip) and the power consumption of the control PC (c. 200 W).

The dispatching mosaic panel and the control system APEL® have been tested in accordance with the standards IEC 801-2 and IEC 801-4.They are resistant to the electromagnetic discharge up to 8 kV if the criterion of serviceability B is observed. A device till 4 kV is proper in supply network and a device till 2 kW is proper in data wiring against the transient disturbance if the criterion of serviceability B is observed. That is why it is possible to use the system and the mosaic panel in such high technologies as the nuclear power supply is.

|

| Mosaic panel controlled by the serial module PSK |

The mosaic panel controlled by the serial module PSK is efficient for middle-size applications where the data are disposable in serial form (RS232, R422, and RS485).

This programmable module is efficient for middle-size applications (typically to 1024 double-point information).

A board signed PSK is the basic module. This module operates a necessary number of slave output and input modules signed as SSK and VSK.

The signalling elements (LED, lamps) and the relay switching are operated by means of the output modules SSK.

The PSK module analyses the situation of the contact devices from the control panel or directly from the technological process by means of the input modules VSK.

Supply voltage of the modules is 24 V DC. This supply voltage can also be used for the power supply of relay inductors and signalling LED diodes that are switched by the SSK modules.

The modular system includes a controlled stabiliser (ZSK module), which enables to change the voltage for the signalling devices excitation. This change enables to change their shine depending on the ambient luminous intensity.

All modules are placed in plastic covers that are adapted to a mounting on a DIN lath.

|

| Mosaic panels for direct connection to technological processes |

|

The direct connection of the mosaic panel is used in small-scale applications where parallel outputs from technology or a superior system are disposable.

The miniaturisation of the construction allows to design panels with small parameters but with big information capacity, so it is possible to reduce demands on place and finance.

The direct connection of the mosaic panel is used for technologies with lower number of displayed quantities (typically to 300 input signals). Displays are connected with technology by means of modules that edit input signals D-IN, eventually by means of an optic separation module OP-IZ200. The module POR 32 functions for signalling of failures.

All these modules are designed to a mounting on a DIN lath.

Communication devices LED are fixed by means of a line of connector modules (K4-K16) that enable to place these devices also in a very small raster (only 8 mm).

|

|

|

|

|

Jiraskova 31

506 01 Jicin

Czech Republic

phone:+420 493 532 352

fax:+420 493 534 931

e-mail: apel@apel.cz

|

|

|

|

|